Waste pipes and soil pipes – no property is complete without these drainage parts. They help remove things from the property to the main drainage systems. Now, there are quite a few parts to these systems and waste and soil pipes both serve different purposes.

To help you understand the different pieces and avoid confusion, we’ve created this handy guide so that you have everything you need to know before buying new soil and waste pipes.

Table of contents

- What is a soil pipe?

- Soil pipe fittings

- What are soil pipes made of?

- What is a waste pipe?

- Waste pipe fittings

- What are waste pipes made of?

- What’s the difference between solvent weld and push fit?

- What is the difference between a soil stack and a waste stack?

Soil pipes explained

The first question is – what is a soil pipe exactly? Well, a soil pipe is a vertical pipe used for transporting sewage into sewer systems. This could be from toilets, urinals, bidets and similar outlets.

If you’ve heard the term soil vent pipe (SVP), this is most likely what it will be referring to. Though other terms exist, such as:

- Soil stack pipe

- “Stink pipe” (a term more commonly associated with the Victorian age)

- Drain waste vent pipe

The pipe’s job is to carry water and solids into the sewer. This primary purpose helps to regulate pressure in the drainage system. Now, other pipes can do the work themselves, but a soil vent pipe is the part to use as it is designed to deal with certain materials others may have difficulty passing. That’s why they are crucial for any drainage system.

The vented section, which includes an air admittance valve, is a prominent feature of the soil pipe. The soil pipe stacks support this part, which usually sits high at the top or near the top of the building. This feature ensures safe ventilation of the gasses produced by the vents passing through into the atmosphere.

Safe ventilation is a must. These gasses can be a health and environmental risk if inefficiently released. As such, the vent being placed high reduces health risks, helps minimise nasty odours and supports environmental protection.

Safety is not the only reason this is a must-do. In fact, UK Building Regulations state the valve must sit at a suitable distance from certain parts of a building. Keeping that in mind, are you confident you know what size soil pipe is needed for your project? Well, let’s look at some soil pipe sizes.

Soil pipe sizes

In the UK, 110mm is the most common size of soil pipe for systems above ground. If underground, 160mm is the most common soil pipe size for the main flow of homes joined together. A lot of components are designed with these sizes in mind, commonly to support suspended horizontal or vertical plastic pipework.

When a toilet soil pipe is connected to the system, it is important to never use a pipe smaller than 100mm to carry the waste from the toilet. This size pipe doesn’t have suitable design elements to deal with solid waste and has a high risk of blockages if used. It’s why 110mm is optimal for these fittings.

You can view some example soil pipe sizes below but check out our range of soil pipes to find a wider selection for your requirements.

| Pipe material | Pipe diameter |

| Cast iron | 50mm |

| Plastic | 110mm |

| Cast iron | 150mm |

| Plastic | 160mm |

If you need soil pipe fittings, you can take a look around our range for these, too, as well as find out more information for specific products.

How high should a soil vent pipe be?

Building Regulations dictate the height of a soil pipe. Approved Document H is a primary focus for this. It outlines drainage and waste disposal Building Regulations in England, covering foul water drainage and disposal.

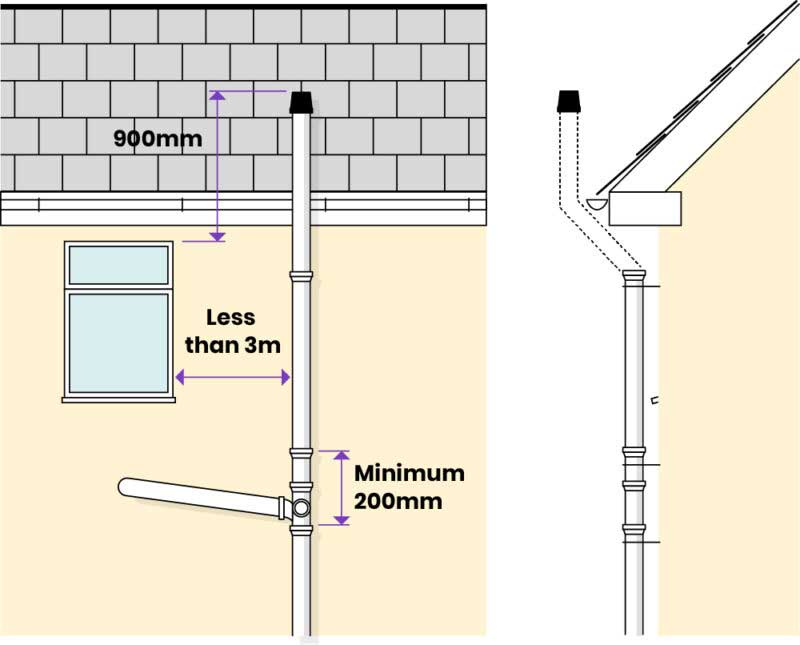

In the document, it states the vent pipe opening must be located at least 900mm above any building within three metres of the pipe. The vent must also be protected, either with a wire cage or perforated to prevent debris or birds from entering the system.

Below is an example of this placement of a soil pipe. Now, if you fit the soil pipe less than three metres from a window, the vent must sit at least 900mm above said window or opening. You must also ensure the pipe sits a minimum of 200mm above the highest water entry point. This will be the highest point where wastewater will reach within the soil pipe.

Soil pipe fittings

Soil pipes are installed using different fittings and parts for a complete system. Here is a breakdown of those features.

Roof terminal

Starting at the top, we have our roof terminal. Its other common name is a vent terminal. It is the part of the system that requires protection using a wire cage or perforated design. This approach helps prevent debris or birds from entering the pipe. As for how it’s fitted, it sits over the exposed open end of the soil vent pipe; speaking of this, on to our next part!

Vent pipe

Next up we have the vent pipe. This sits up through the roof at the top of the soil stack. This is where harmful gasses pass through and escape into the atmosphere.

Note: If you want an internal soil vent pipe, an air admittance valve can be used instead of vent pipes to enable the soil stack pipe to be fitted inside the property.

Weathering collar and weathering slate

Moving on we have the weathering collar, an added form of protection for diverting rainwater from falling directly onto the weathering slate.

Even though weathering slate typically creates a tight seal around the soil vent pipe, it adds extra protection which further improves the longevity of this part of the system when paired with the weathering collar.

Offset bend and bends

Offset bends come in two specific types – top and bottom.

The top offset bend pieces are a ring seal socket with a solvent bottom. The bottom offset bend pieces are a solvent socket with a spigot bottom.

These parts sit at the top of the soil stack for directional changes. They’re joined together using a short pipe that sits between the two solvent weld points.

Then there are your standard bends. These are used to change the direction along the horizontal sections of a soil pipe run.

Branch and boss pipe

Branches are your piece for connecting toilets, urinals and bidet soil pipes to the soil stack. With that said, a boss pipe is also a connection point, but it is typically manufactured with multiple entry points to enable the connection of waste pipes to the soil stack from more than one point of entry.

Pipe clips and socket clips

The pipe clip is for securing soil pipes against a wall and providing support around joints. They are typically the clip of choice for plain-ended pipes.

As for socket clips, these have the same purpose but are more suited for socket ends.

Coupling (slip coupling)

Couplings come in two designs – double or single-socketed. Whichever is required, they’re used to connect pipe lengths together.

Pipe lengths

A pipe length is your standard pipe. Its design is for the soil stack and breaching connections to property bathroom facilities (toilets, urinals and bidets).

Common pipe lengths are 3m or 4m, but you’ll need to check what lengths you need before buying to ensure you’re fitting the right pipe for the job.

Access pipe/underground pipe

The name for this one is quite handy for stating its use, which is that it’s the point of access to the soil stack. This matters because it allows inspections, cleaning and rodding to be carried out. The pipe can also be suitable as a connection point for waste pipes if boss pipes can be fitted to the side.

What are soil pipes made of?

Cast iron is no longer the only material of choice for soil pipes. Now there are plastic pipes and fitting solutions which have unique benefits.

Plastic soil pipes

A plastic soil pipe is available in an array of colours and has plenty of other individual benefits:

- Lightweight – This helps reduce transportation costs and installation times.

- A smoother internal surface – This allows risk reduction of materials clogging systems and causing blockages.

- Flexible – This makes them usable in an array of projects.

- Tough resistance to chemicals – This reduces detrimental effects risks from using bleach and toilet cleaner.

- More length varieties – So fewer joints are needed (unlike cast iron).

- Long-lasting and cost-efficient – Their material is durable and easy to maintain.

uPVC soil vent pipe systems are also incredibly easy to install as many parts can be compatible with other systems. If this isn’t possible, conversion fittings exist to allow easy connections of parts to systems. Take care if you are opting for this, however, because different connections are advised and not to be mixed.

Despite the plastic soil pipe’s benefits as a worthy investment for systems, discuss your approach with a professional. They can help confirm alterations or repairs if the property does not have a cast iron soil stack installed.

If a cast iron soil pipe is in place, this will need assessment for asbestos. Many older soil pipe systems contain this dangerous mineral and will need to be removed by professional means if you do not have the expertise to do so yourself.

Cast iron soil pipes

Many modern properties opt for alternative plastic material systems, but a lot of older properties (some new, as well) still opt for cast iron soil pipes to be installed. This is especially true for older properties built or refurbished before the year 2000.

Why change the system? Well, as mentioned earlier, older cast iron soil stacks have a higher risk of containing asbestos, which must be removed and disposed of safely through the correct means by professional removers – especially if you do not have the skills needed for the job.

- Nowadays cast iron soil pipe attributes today are as follows:

- Long-lasting design – Some cast iron systems can last as long as 100+ years.

- 100% recyclable – Many are now a combination of 100% scrap and recycled metals.

- Low maintenance – One annual inspection is advised per year (minimum).

- Heat damage resistance – Can withstand exposure to higher temperatures.

- Won’t deflect under heavy loads – Can endure intense weather like rain or snow.

Explaining waste pipes

Now we know the basics of soil pipes, on to the next question – what is a waste pipe?

The simple explanation is waste pipes are used for carrying greywater from appliances that may have used water. It may be water from a waste pipe connected to a washing machine or a sink waste pipe, which has smaller diameters than a soil pipe. This narrowness is a design choice because it is only for carrying water and not transporting hefty solids like soil vent pipes.

Waste pipes also don’t need the same venting systems as soil pipes as wastewater doesn’t usually generate harmful gasses, unlike contaminated water. So, no need for it to be vented high above ground level.

At the same time, if your property’s waste system is separate from the soil system and not connected to the soil stack, the addition of ventilation can still be added, if required. For waste systems that are connected to soil pipe systems, ventilation should already be in place.

Back to separate systems, these must still be looked at to ensure the waste pipes are not at risk of contaminated water flowing through them. For example, toilet waste pipe solutions do exist but are uncommon, so always check the system already in place to prevent future issues in your home and your health from being compromised.

Note: If you are ever unsure about your system, always seek professional advice.

Waste pipe sizes

In the UK, 32mm, 40mm and 50mm are the most common sizes of waste pipes for systems. Each has its own uses, in most cases.

- 32mm: Typically used for appliances presenting low volumes of water to the system (e.g. small hand basins).

- 40mm: Normally used for kitchen sinks, showers and baths.

- 50mm: A large pipe commonly suited to commercial applications or connecting multiple waste pipes to a single flowing system.

As mentioned above, combined soil and waste systems are usually ventilated already. If this is the case, your focus will be making sure you have the correct size of pipe for the application.

Now, if your systems are separate, the focus will be ensuring contaminated water does not flow down the waste pipes.

Note: If you are ever unsure about your system, always seek professional advice.

Onto waste pipe sizes, here’s an example range of different ones available. More can be found via our selection of plastic waste pipes to find one suitable for your requirements.

| Pipe material | Pipe diameter |

| Plastic | 32mm |

| Plastic | 40mm |

| Plastic | 50mm |

If you need waste pipe fittings, you can visit our range of products for these, too.

Waste pipe fittings

Waste pipe systems have some similarities to soil vent systems when it comes to their makeup. This includes:

- Pipe lengths

- Couplings

- Pipe clips

- Bends

- Conversion bends

- Air admittance valves

More information about these specific parts can be found in the soil pipe fittings section. So, now onto the other parts included in waste pipe systems.

Pipe tees

A tee facilitates the connection of two or three waste pipes at a 92.5-degree angle. For a pair of waste pipes, a single tee is used more often, while a cross tee is used for connecting three waste pipes.

Pipe caps

This piece caps off outlets not in use during the system’s operation to help avoid unnecessary spillage.

Pipe reducers

Sometimes you’ll need to connect pipes of different sizes. A reducer can make this easier, helping to convert the diameter of the pipe. For example, if you’re connecting a 32mm waste pipe to a 40mm waste pipe, a reducer can make this connection work to ensure the system flows efficiently.

Waste traps

A waste trap sits beneath the appliances connected to the systems. Sinks, bathtubs, showers and any other appliances with wastewater. When the system is operational, this feature will create a water trap, reducing the risk of bad smells rising back up through the drain.

What are waste pipes made of?

Waste pipe materials aren’t too different from older designs, with many properties still using systems made from copper, iron or lead. They can be combined with other materials or manufactured in a singular.

Copper waste pipes

Copper is still a firm favourite for professionals as its benefits outweigh a lot of other materials:

- Flexible – Ideal when fitting systems in tight spaces and joint flexibility.

- High damage resistance – Particularly beneficial if subject to vibrations.

- Aesthetic appeal – Looks incredible, smart and fits well with traditional-style properties especially.

If a copper pipe system exists already, repairs and installing more pipes are possible in a lot of circumstances. In fact, manufacturers know this and have done their best to help with these installations for years now. Many even offer parts (plastic or otherwise) to fit with existing systems.

Pairing plastic waste pipes with existing copper systems? Look at our range here at Plumbing Superstore to see what can fit into your existing waste pipe system.

Plastic waste pipes

The popularity of plastic is growing for waste pipes and there are plenty of reasons as to why this is:

- Cost-efficient – Their maintenance and initial costs can often be far less than their material counterparts (i.e. copper).

- Higher resistance – Particularly when it comes to corrosion and impact damage.

- Easier installation – Many pipes now have easy connections thanks to push-and-click together solutions (amongst other fitting alternatives).

- Quieter performance – If exposed to high pressure and water speeds then you’ll likely be able to use plastic pipes to minimise the noise of clanking and clattering.

What’s the difference between solvent weld and push fit?

If an existing system, plastic soil or waste, is in place or you want/need to install a new system, two main types of pipes exist that you can choose from. Both are quick-fit solutions, but each has unique differences. Here’s a breakdown of each:

Push-fit soil pipes and push-fit waste pipes

The push-fit model is typical if you want to install systems without tools or extra fixings. Instead, they feature a captive ring seal to create watertight joints without compromising flexibility to allow thermal movement to occur.

This solution is also not permanent, which makes removals and/or replacements much easier.

Solvent weld soil fittings and solvent weld waste fittings

As its name implies, solvent welding is the action of using solvent cement to fit two pipes or a pipe and fitting together.

Solvent is applied to the outside of the pipe and inside of the fitting. Each part is then pushed together and twisted to ensure a tight fit and form a permanent weld between the two fittings.

This type of connection is commonly used in areas where there’s a higher risk of impact on the system, such as public buildings, and is a highly recommended choice if this is the case.

What is the difference between a soil stack and a waste stack?

An easy difference to spot – soil stacks are typically larger than waste stacks.

Why is this? Well, soil pipes need to allow passage of solids commonly found in soil water. You can find out more about common soil pipe dimensions and waste pipe dimensions in the tables above.

Now you know the differences, you might want to know more about installing a soil pipe? Perhaps you want to know more tips about plumbing with plastic pipes or know how to unblock drains with a drain rod? We’ve got an array of advice about those topics and more to help you out.